Each type of metal used to make a metal roof has different properties. It is important to consider how these properties will affect the cost, longevity, durability, and appearance of the roof over time. Before you invest in a metal roof, make sure the type of metal you choose gives you the advantages that best meet your needs and the needs of your home.

Steel Roofs

Steel roofing has been the most commonly used metal in commercial construction for years. Because it is the most recycled material in the world and very readily available, it comes with a lower price tag and is gaining popularity for residential roofing projects. It lasts about 40 – 60 years, but it must be properly maintained to avoid eventual corrosion. It’s also one of the most durable materials used in roofing and performs well in hail storms and high winds. Steel is a good choice for any climate!

Copper Roofs

Copper has been used in roofing for centuries. Because it is lightweight and malleable, it is easy to install. With the proper conditions and maintenance, a copper roofing system can last more than 100 years. This can make the expense a worthwhile investment. Over time, the new penny color will change to a blue-green or brown patina, making each copper roof unique. It is a softer metal, which means that rain and hail storms will be quieter inside the home. On the other hand, it also means that it will dent more easily due to hail impacts, falling tree limbs, etc. At the end of the roof’s life, copper is 100% recyclable.

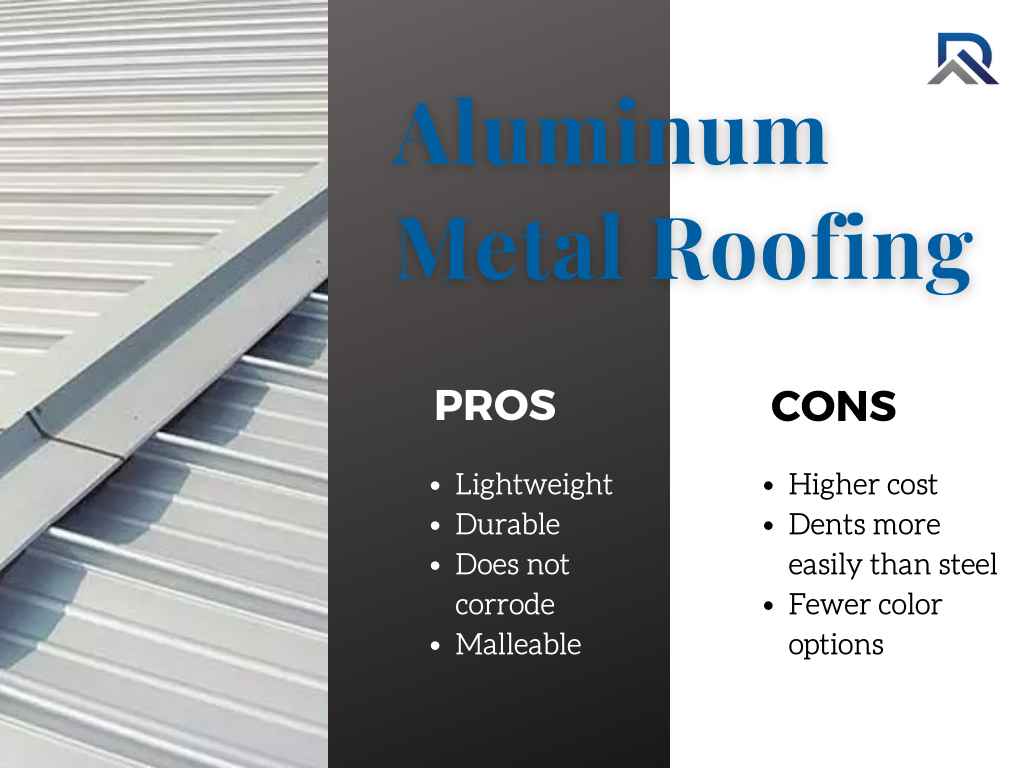

Aluminum Roofs

Aluminum is lightweight and malleable, making it easy to install on any roof. It is a great roofing material for humid environments because it does not corrode. Instead, the metal reacts with oxygen in the air and creates a layer of aluminum oxide, which seals and protects the inner layer of metal from corrosion or damage. The major disadvantage of aluminum roofing is the higher cost. The high price often causes aluminum roofing materials to be made thinner than others. This also makes it more susceptible to denting.

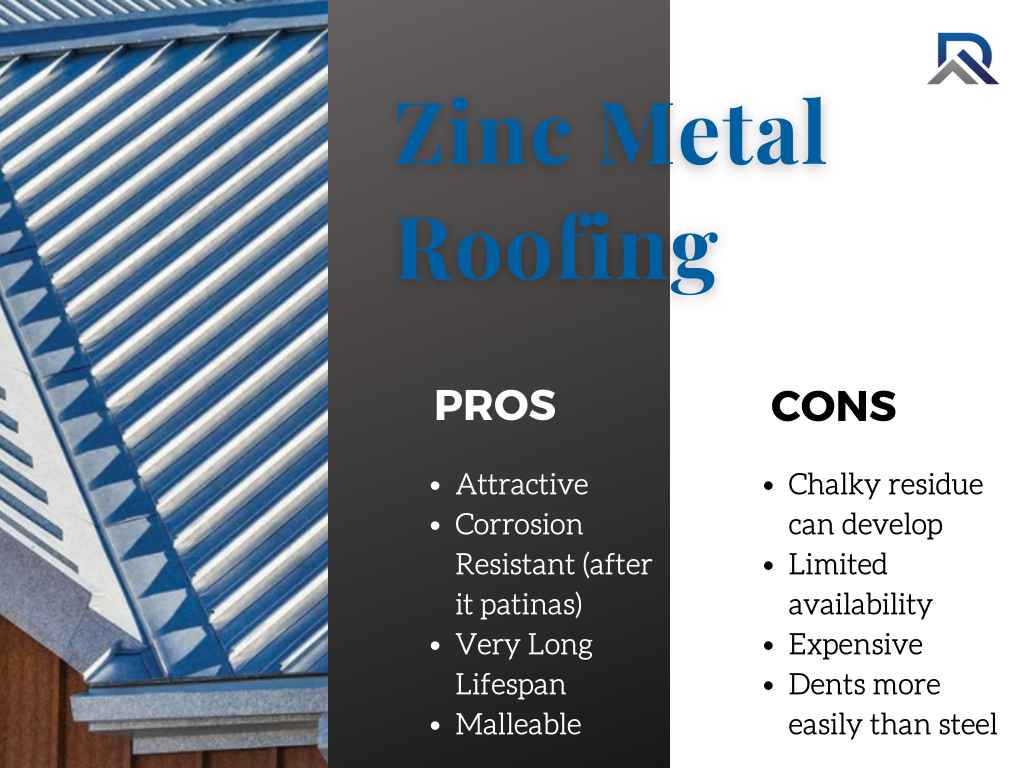

Zinc Roofs

Zinc can be shaped and manipulated for any roofing project, and it can last more than 100 years! Once exposed to moisture and carbon dioxide in the air, an outer layer of zinc carbonate will form. This blue-gray patina protects the inner layers of zinc from corrosion, and this process happens any time the roof is dented or scratched, so the roof is constantly preserved. A white chalky residue can develop over the patina in areas where water runs on the roof – like the valleys. Although it’s unattractive, it can be washed off easily. There are a few suppliers of zinc roofing materials in the United States, but choices may be limited. Make sure your zinc roof is installed by experienced professionals in order to avoid trapped moisture and rotting beneath the metal.

Tin Roofs

The tin roofing that is sold today is actually steel that is coated with tin. For this reason, it now shares many of the pros and cons of steel roofing, although the availability is much more limited.

Let Rojas Roofing Make Your Decision Easier

If you’re considering installing a metal roof on your home or business and you’d like more information about metal roofing systems, please don’t hesitate to contact us at (317) 864-6193 or fill out our contact form.